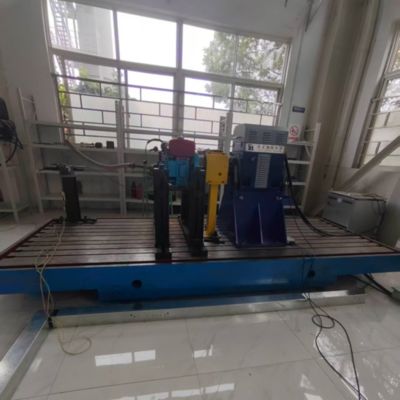

SSCD22-1000-4000 Sistema banco prova dinamometrico elettrico per motore diesel da 22kW

1. Descrizione del sistema banco prova dinamometrico elettrico per motore diesel SSCD22-1000-4000 da 22kW

Questo sistema, incentrato su un piccolo dinamometro CA e compatibile con piccoli motori diesel da 22kW, impiega la tecnologia dell'inverter a frequenza variabile a quattro quadranti per un efficiente recupero dell'energia (efficienza di reintroduzione >85%). Dotato del sistema di misurazione e controllo XLE-1000, supporta l'acquisizione e l'analisi simultanee multicanale dei parametri chiave. Esegue automaticamente cicli di prova specificati in standard come GB/T 18297 e integra apparecchiature come un piccolo misuratore di fumo e un misuratore di flusso d'aria ad alta precisione, soddisfacendo le esigenze di test completi delle prestazioni di piccoli motori diesel utilizzati in mini veicoli commerciali, piccole macchine agricole e apparecchiature di alimentazione per uso generale.

2. Condizioni di fabbrica per l'installazione delle apparecchiature

| Parametri |

Valori |

Parametri |

Valori |

| Altitudine |

Meno di 1000 metri |

Umidità di fabbrica |

≤85% |

| Spessore della fondazione |

>200mm |

Temperatura di fabbrica |

5°C~40°C |

| Portata del pavimento di fabbrica |

4t/㎡ |

Elettricità |

380V±10% trifase 50Hz |

3. Standard di riferimento del sistema banco prova dinamometrico elettrico per motore diesel SSCD22-1000-4000 da 22kW

1) GB20891-2014 "Limiti e metodi di misurazione degli inquinanti di scarico dai motori diesel per macchinari mobili non stradali" (applicabile ai modelli non stradali di piccola potenza)

2) GB/T 18297-2001 "Metodi di prova delle prestazioni dei motori automobilistici"

3) GB/T 17692-2003 "Metodi di prova per la potenza netta dei motori automobilistici e dei motori di azionamento"

4. Componenti del sistema banco prova dinamometrico elettrico per motore diesel SSCD22-1000-4000 da 22kW

1) Dinamometro elettrico: Piccolo dinamometro CA Seelong con flangia di coppia HBM T40B (0-500 Nm, adatto per intervalli di coppia a bassa potenza), raffreddamento ad aria (struttura di dissipazione del calore semplificata), accoppiamento elastico per ridurre le vibrazioni e supporta il funzionamento stabile da 0-4500 giri/min (in linea con le caratteristiche di alta velocità dei motori a bassa potenza).

2) Sistema inverter a frequenza variabile: Convertitore di frequenza piccolo serie ABB ACS880 con controllo diretto della coppia (DTC), precisione di controllo di 0,01 Hz, adattato per scenari di recupero energetico a bassa potenza ed efficienza di feedback energetico >85% (evitando sprechi di energia nei moduli ad alta potenza).

3) Sistema di misurazione e controllo XLE-1000: Fornisce il controllo generale del banco prova, consentendo l'impostazione delle condizioni operative a bassa potenza tramite comunicazione bus con il sistema inverter. Integra apparecchiature ausiliarie esterne per il controllo centralizzato e supporta l'esecuzione automatizzata di processi di prova dedicati per motori a bassa potenza (come la stabilità al minimo e i test del consumo di carburante a basso carico).

4) Sistema di acquisizione dati: Modulo di acquisizione ad alta velocità a 16 canali (frequenza di campionamento 200 Hz, soddisfacendo le esigenze di acquisizione dei parametri a bassa potenza) con funzione integrata di condizionamento del segnale, che trasmette in tempo reale i parametri chiave come coppia, velocità, consumo di carburante al sistema di misurazione e controllo per l'analisi e l'archiviazione.

5) Apparecchiature ausiliarie: Termostato per liquido di raffreddamento piccolo (15 l/min, adatto per requisiti di raffreddamento a bassa potenza), piccolo misuratore di fumo opaco AVL, acceleratore elettronico a doppio canale, piccola valvola di contropressione di scarico e sensore di pressione del carburante a bassa pressione (adatto per sistemi di alimentazione del carburante per motori a bassa potenza).

5. Parametri tecnici del dinamometro elettrico per motore diesel da 22kW

| Parametri |

Indicatori tecnici |

| Produttori di motori |

Seelong |

| Potenza nominale |

22kW |

| Coppia nominale |

210Nm |

| Velocità nominale |

1000rpm |

| Velocità massima |

4000rpm |

| Intervallo di velocità a coppia costante |

0-1000rpm |

| Intervallo di velocità a potenza costante |

1000-4000 rpm |

| Modelli di sensori di coppia |

T40B |

| Intervallo del sensore di coppia (Nm) |

0-500 Nm |

| Grado di precisione |

0,05%FS |

6. Vantaggi principali del sistema banco prova dinamometrico elettrico per motore diesel SSCD22-1000-4000 da 22kW

1) Adattamento preciso per motori a bassa potenza: L'algoritmo di carico è ottimizzato per i modelli di classe 22kW, che possono eseguire stabilmente condizioni operative specifiche a bassa potenza come carico leggero e minimo, soddisfacendo i requisiti di un test di resistenza di 500 ore (in linea con l'intensità di utilizzo dei motori a bassa potenza).

2) Design leggero e a risparmio energetico: Il peso complessivo dell'apparecchiatura è inferiore del 15% rispetto a quello di un banco prova tradizionale con la stessa potenza. In combinazione con un sistema di recupero energetico a bassa potenza, il consumo energetico del test è ridotto di oltre il 30% rispetto a una macchina a carico resistivo, rendendolo adatto a scenari di test in piccoli lotti in laboratori.

3) Basso costo e facile funzionamento e manutenzione: I componenti modulari sono di piccole dimensioni e non richiedono infrastrutture su larga scala per l'installazione; le parti soggette a usura sono di specifiche universali e hanno bassi costi di sostituzione, con un tempo di manutenzione annuale ≤15 ore (abbassando la soglia di utilizzo per le piccole imprese).

4) Compatibilità flessibile in più scenari: Supporta i test dei motori per micro veicoli commerciali, piccole macchine agricole e gruppi elettrogeni da 10-30kVA. Può cambiare rapidamente le modalità operative per soddisfare le diverse esigenze di test dei modelli a bassa potenza.

7. Applicazioni del sistema banco prova dinamometrico elettrico per motore diesel SSCD22-1000-4000 da 22kW

1) Ricerca e sviluppo di micro veicoli commerciali/autocarri leggeri: I motori diesel da 22kW per mini autocarri inferiori a 3 tonnellate e autobus leggeri a 6-9 posti vengono testati per la stabilità al minimo, il consumo di carburante a basso carico e le prestazioni delle emissioni.

2) Verifica di piccole macchine agricole: I motori diesel adatti per trattori a piedi e piccole mietitrici vengono utilizzati per simulare condizioni operative a basso carico sul campo per verificare l'abbinamento della potenza e l'affidabilità.

3) Test di potenza generale di piccole dimensioni: Fornisce la calibrazione della potenza, la valutazione del consumo di carburante e i test delle prestazioni di avviamento per gruppi elettrogeni da 10-30kVA e motori diesel da 22kW per piccole pompe idrauliche industriali.

4) Controllo qualità della manutenzione post-vendita: Utilizzato da officine di riparazione auto e stazioni di macchine agricole per verificare il recupero delle prestazioni dei motori diesel a bassa potenza dopo la riparazione e rilasciare rapidamente semplici rapporti di prova.

8. Elenco dei modelli del sistema banco prova dinamometrico elettrico per motore diesel

| Modello |

Potenza (KW) |

Coppia (Nm) |

Velocità nominale (rpm) |

Velocità massima (rpm) |

Precisione della misurazione della coppia |

| SSCD15-1000/4000 |

15 |

143 |

1000 |

4000 |

0,2%FS |

| SSCD22-1000/4000 |

22 |

210 |

1000 |

4000 |

0,2%FS |

| SSCD30-1000/4000 |

30 |

286 |

1000 |

4000 |

0,2%FS |

| SSCD45-1000/4000 |

45 |

430 |

1000 |

4000 |

0,2%FS |

| SSCD60-1000/4000 |

60 |

573 |

1000 |

4000 |

0,2%FS |

| SSCD90-1000/3500 |

90 |

859 |

1000 |

3500 |

0,2%FS |

| SSCD110-1000/3500 |

110 |

1050 |

1000 |

3500 |

0,2%FS |

| SSCD160-1000/3500 |

160 |

1528 |

1000 |

3500 |

0,2%FS |

| SSCD200-1000/3300 |

200 |

1910 |

1000 |

3300 |

0,2%FS |

| SSCD250-1000/3300 |

250 |

2387 |

1000 |

3300 |

0,2%FS |

| SSCD300-1000/3300 |

300 |

2865 |

1000 |

3300 |

0,2%FS |

| SSCD30-1500/5000 |

30 |

191 |

1500 |

5000 |

0,2%FS |

| SSCD45-1500/5000 |

45 |

286 |

1500 |

5000 |

0,2%FS |

| SSCD60-1500/5000 |

60 |

382 |

1500 |

5000 |

0,2%FS |

| SSCD90-1500/5000 |

90 |

573 |

1500 |

5000 |

0,2%FS |

| SSCD132-1500/4500 |

132 |

840 |

1500 |

4500 |

0,2%FS |

| SSCD160-1500/4500 |

160 |

1019 |

1500 |

4500 |

0,2%FS |

| SSCD200-1500/4000 |

200 |

1273 |

1500 |

4000 |

0,2%FS |

| SSCD250-1500/4000 |

250 |

1592 |

1500 |

4000 |

0,2%FS |

| SSCD300-1500/3800 |

300 |

1910 |

1500 |

3800 |

0,2%FS |

| SSCD315-1500/3800 |

315 |

2005 |

1500 |

3800 |

0,2%FS |

| SSCD355-1500/3800 |

355 |

2260 |

1500 |

3800 |

0,2%FS |

| SSCD400-1500/3800 |

400 |

2546 |

1500 |

3800 |

0,2%FS |

| SSCD500-1500/3800 |

500 |

3183 |

1500 |

3800 |

0,2%FS |

| Può essere personalizzato |

A: Supportiamo un piccolo ordine di prova di 1 pezzo per i prodotti a stock.

A: Si prega di lasciare la propria e-mail e vi invieremo il vostro campionario elettronico.

A: Normalmente 40% di deposito T/T, pagare per intero prima della spedizione.

A: Il ciclo di produzione dei dinamometri è di 6-8 settimane, il ciclo di produzione dei sensori è di 2-3 settimane, per altri prodotti si prega di contattarci.

A: Lasciaci la tua e-mail, il nostro personale tecnico comunicherà con te il piano dettagliato.

A: Certo, sei sempre il benvenuto per una visita.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!