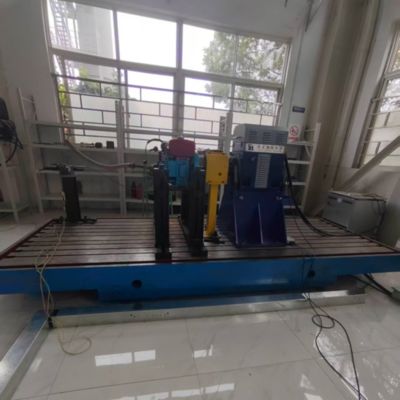

Codice di prova del motore UAV SSCG250-3000/8000 da 250 kW

1. SSCG250-3000/8000 250 kW UAV Motor Test Bench Descrizione del componente

Il banco di prova dei motori UAV SSCG250-3000/8000 da 250 kW è un sistema di prova completo progettato appositamente per la ricerca e la verifica dei motori UAV ad alta potenza.Questo sistema integra un dinamometro elettrico ad alta precisione, un sistema modulare di misura e controllo e un'unità di acquisizione dati multicanale, che consente una valutazione completa dei principali parametri di prestazione quali coppia, velocità, potenza,e consumo di carburante dei motori a turboasse/turboelica di classe 250 kW.

| Nome del componente |

Specificativi essenziali |

Marchio |

| SSCG250-3000/8000 dinamometro elettrico |

Potenza: 250 kW, velocità nominale: 3000 giri al minuto, velocità massima: 8000 giri al minuto, coppia nominale: 796Nm, raffreddato ad aria |

Seelong |

| Flancia di coppia |

0-1000Nm, precisione: 0,2%FS |

HBM |

| Sistema di inverter a frequenza variabile |

Marca ABB, 250kW, trifase AC 380V ± 10% di tensione di ingresso, con molteplici protezioni contro sovraccarico, sovratensione e surriscaldamento. |

ABB |

| Sistema di misurazione e controllo XLE-1000 |

PC industriale: IPC710; CPU: Intel Core I7; Memoria: 32 GB DDR4; Hard Drive: 1 TB SSD; software di sistema di misurazione e controllo XLE-1000 preinstallato (supporta acquisizione dati in tempo reale, analisi delle curve,e generazione di relazioni). |

Seelong |

| Sistema di acquisizione dei dati |

Comprende un modulo di acquisizione a bassa temperatura (6 canali ), un modulo di acquisizione ad alta temperatura (8 canali ), un modulo di acquisizione analogica (8 canali ),un sensore di acquisizione a bassa temperatura (PT100), un sensore ad alta temperatura, un sensore di pressione, un sensore di pressione atmosferica, un sensore di temperatura e umidità e una scatola di acquisizione dati, ecc. |

Seelong |

| Attuatore di servoacceleratore |

Performance: forza di azionamento 150N, corsa 120mm

Simulazione elettronica dell'acceleratore: doppio canale 0-2,5 V/5 V

|

Seelong |

| Misuratore del consumo di carburante |

Tipo di pesatura, gamma di misura: 10-50 kg/h, precisione: 0,2%FS |

Seelong |

| Ventilatore a frequenza variabile centrifuga |

Utilizzato per la dissipazione del calore del dispositivo sottoposto a prova; Potenza: 40 kW |

Seelong |

| Opzionale - Accoppiamento |

Torsione ammissibile: 575Nm; velocità ammissibile: 18000 giri/min |

Seelong |

| Opzionale - supporto motore |

Supporto per motori non standard, a forma di L, spessore della parete > 50 mm |

Seelong |

| Opzionale - piastra in ghisa |

Materiale: HT300 (resistenza alla trazione ≥ 300 MPa); piattezza: ≤ 0,05 mm/m; rugosità superficiale: Ra≤1,6 μm; ammortizzatori e piastre in ghisa garantiscono la stabilità durante le prove ad alta velocità. |

Seelong |

| Opzionale - ammortizzatori |

Tipo: ammortizzatore a molla; carico nominale: 100-300 kg/unità; coefficiente di ammortizzazione: 0,2-0.3Frequenza di vibrazione applicabile: 5-10 Hz; L'ammortizzatore e la piastra in ghisa garantiscono la stabilità durante le prove ad alta velocità. |

Seelong |

2. SSCG250-3000/8000 250 kW Dinamometro elettrico Parametri tecnici

| Parametri |

Specificità |

| Modello |

SSCG250-3000 /8000 |

| Potenza nominale |

250 kW |

| Velocità nominale |

3000 giri al minuto |

| Torsione nominale |

796Nm |

| Velocità massima |

8000 giri al minuto |

| Metodo di raffreddamento |

con raffreddamento ad aria |

| Livello di protezione |

Protezione IP54 |

| Capacità di sovraccarico |

150% della potenza nominale |

| Accuratezza della misurazione della coppia |

±0,2%FS |

| Precisione di misura della velocità |

±1 giri al minuto |

3. SSCG250-3000/8000 250kW Motore UAV banco di prova Vantaggi principali

1) Controllo ad alta precisione: sia la flangia della coppia che il misuratore di consumo di carburante raggiungono una precisione dello 0,2% FS e l'algoritmo PID è combinato per realizzare il controllo delle fluttuazioni di velocità (valore tipico < ± 0,1%),garantire l'affidabilità dei dati di prova.

2) Gestione energetica in quattro quadranti: supporta il funzionamento in doppia modalità del motore elettrico/generatore, con un'elevata efficienza di feedback energetico e si adatta alle esigenze di prova in condizioni complete dei motori dei droni.

3) Scalabilità modulare: Il sistema di misura e controllo XLE-1000 supporta l'acquisizione di dati multicanale e i componenti opzionali possono essere adattati in modo flessibile a diversi scenari di prova, migliorando la flessibilità del sistema.

4) Protezione della sicurezza: Il sistema di conversione di frequenza integra la protezione da sovraccarico, sovratensione e surriscaldamento per garantire la stabilità durante le prove ad alta velocità (8.000 giri al minuto) e ridurre il rischio di guasto dell'apparecchiatura.

5) Progettazione a bassa vibrazione: L'ammortizzatore è adattato ad una frequenza di vibrazione di 5-10 Hz e, insieme alla piastra in ghisa,garantisce l'accuratezza della prova e riduce l'impatto delle interferenze esterne sui risultati della prova.

4. SSCG250-3000/8000 250kW UAV Motore banco di prova aree di applicazione

1)Sviluppo di motori per veicoli aerei senza pilota (UAV): prova completa del processo di avvio, accelerazione e frenata per motori a turboasse/turboelica di classe 250 kW per verificare i parametri delle prestazioni del motore.

2)Verificazione della propulsione aeronautica: Supporta il test di durata di materiali difficili da lavorare, come leghe ad alta temperatura e leghe di titanio, e valuta l'affidabilità del motore in condizioni di funzionamento estreme.

3)Prova di potenza di nuova energia: adattamento alla valutazione dell'efficienza energetica dei sistemi di propulsione ibridi per ottimizzare l'efficienza di utilizzo dell'energia.

4)Calibrazione dei motori industriali: utilizzato per la calibrazione di alta precisione delle caratteristiche di coppia motore-velocità, migliorando la precisione del controllo del motore.

5. SSCG250-3000 /8000 250kW UAV Motore di prova bench standard di riferimento

Norme di sicurezza elettrica: soddisfa i requisiti di efficienza energetica di IEC 60034-30-1, garantendo un funzionamento stabile dell'apparecchiatura a 380V±10%.

Norme di acquisizione dei dati: seguire il sistema di gestione delle misurazioni ISO 10012 per garantire l'accuratezza dei sensori (come i sensori di temperatura PT100) e la coerenza dell'acquisizione dei dati.

Norme di adattabilità ambientale: soddisfare i requisiti di prova ambientale della serie GB/T 2423 per garantire che l'apparecchiatura possa funzionare normalmente in un ambiente compreso tra -10°C e 40°C.

6. Motore UAV Dinamometro elettrico banco di prova elenco dei modelli

| Modello |

Potenza (kW) |

Torsione (Nm) |

Velocità nominale (rpm) |

Velocità massima (rpm) |

Accuratezza di misurazione della coppia |

| SSCG30-3000/10000 |

30 |

95 |

3000 |

10000 |

00,2% FS |

| SSCG45-3000/10000 |

45 |

143 |

3000 |

10000 |

00,2% FS |

| SSCG60-3000/10000 |

60 |

191 |

3000 |

10000 |

00,2% FS |

| SSCG75-3000/10000 |

75 |

238 |

3000 |

10000 |

00,2% FS |

| SSCG90-3000/10000 |

90 |

286 |

3000 |

10000 |

00,2% FS |

| SSCG110-3000/10000 |

110 |

350 |

3000 |

10000 |

00,2% FS |

| SSCG132-3000/10000 |

132 |

420 |

3000 |

10000 |

00,2% FS |

| SSCG160-3000/10000 |

160 |

509 |

3000 |

10000 |

00,2% FS |

| SSCG200-3000/8000 |

200 |

637 |

3000 |

8000 |

00,2% FS |

| SSCG250-3000/8000 |

250 |

796 |

3000 |

8000 |

00,2% FS |

| SSCG300-3000/7500 |

300 |

955 |

3000 |

7500 |

00,2% FS |

| SSCG350-3000/7500 |

350 |

1114 |

3000 |

7500 |

00,2% FS |

| SSCG400-3000/7500 |

400 |

1273 |

3000 |

7500 |

00,2% FS |

| Potenza, velocità. Distanzaa)e il numero di moduli di acquisizione può essere personalizzatocome richiesto. |

7Servizio di consegna e post-vendita

Consegna: i modelli standard spediscono entro 90 giorni; i modelli personalizzati spediscono entro 90-180 giorni (compresa la logistica internazionale e l'assistenza in dogana).

Servizio post-vendita: garanzia di 1 anno per i componenti principali (dinamometro, flange di coppia), supporto tecnico bilingue (cinese e inglese) per tutta la vita (tempo di risposta ≤ 4 ore);i pezzi di ricambio sono spediti a livello nazionale entro 24 ore e consegnati a livello internazionale entro 7 giorni■ 1,5 giorni di formazione operativa gratuita; supporto per il debug remoto (computer, inclusa la guida alla configurazione della soluzione modulare).

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!